Last updated on October 29, 2022

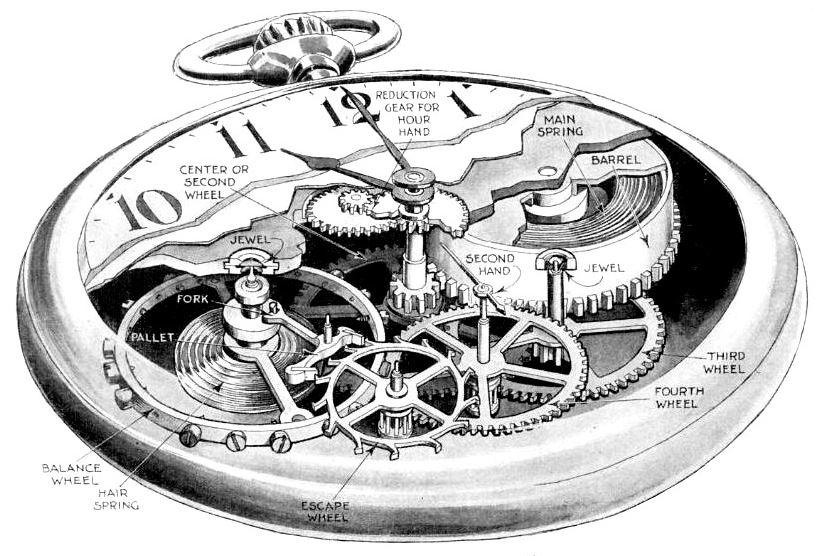

These are the primary watch movement components found in most antique pocket watches, although the visual layout may change between models. In this post, we are looking at an antique pocket watch using a going barrel. We will examine the main components and how they interact with each other. Some of the components are not visible on the cut-away image.

The Mainspring

The mainspring is the power source for the movement. A mainspring is a spiral spring of metal ribbon. It is coiled around an arbor (axle) and enclosed inside a cylindrical box called the barrel which is free to turn. The spring is attached to the arbor at its inner end, and to the barrel at its outer end. The mainspring is held in place at the arbor by a metal collar called a collet. Winding the watch turns the arbor, which tightens the mainspring, wrapping it closer around the arbor. The arbor has a ratchet attached to it, with a click to prevent the spring from turning the arbor backwards and unwinding.

Mainspring barrel – a barrel is a cylindrical metal box closed by a cover, with a ring of gear teeth around it, containing the mainspring.

Ratchet wheel – The ratchet wheel sits on top of the barrel and is attached with a screw to the barrel’s arbor. When a watch is wound, the ratchet wheel turns and tightly coils the mainspring. The click holds the ratchet wheel in place so that the mainspring cannot unwind backwards. The clicking noise heard when winding a watch is the click tapping against each tooth of the ratchet wheel as it turns.

Mainspring arbor – To wind the mainspring the arbor is turned so that the spring is wound around the arbor. The mainspring arbor mounts the ratchet wheel and hooks the wrapped mainspring.

Crown wheel -when the winding shaft is set in motion the crown wheel transfers the energy to the ratchet wheel.

The Gear Train

Going barrel – acts as the first wheel and meshes with the centre (or second) wheel pinion. This transfers power from the mainspring to the gear train. The going barrel turns once approximately every eight hours.

Centre wheel – the centre wheel turns once per hour. This wheel has a shaft that goes through to the dial. On the dial side is the cannon pinion, which is attached to the minute hand. The cannon pinion drives a small 12-to-1 reduction gear, called the motion work, that turns the hour wheel and hand once for every 12 revolutions of the minute hand. The centre wheel meshes with the third wheel.

Safety or reversing pinion – If the mainspring snaps and pressure is suddenly reversed, the pinion unscrews and no reverse power is applied to the rest of the movement.

Third wheel – the third wheel is powered by the centre wheel and meshes with the fourth wheel pinion.

Fourth wheel – the fourth wheel is driven by the third wheel and meshes with the escape wheel pinion. The minute hand is mounted on the fourth wheel, which turns once per minute.

The Escapement

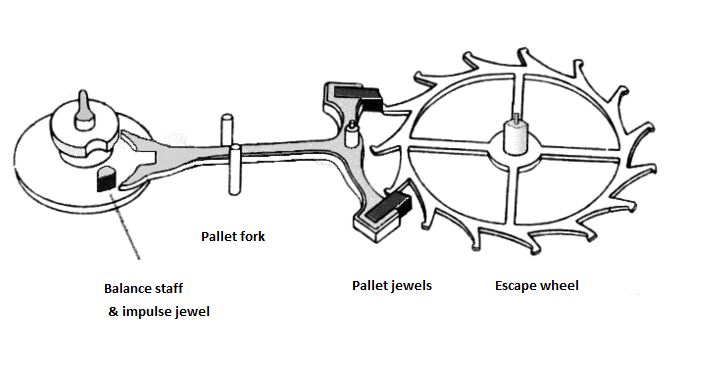

Escape wheel – the escape wheel is driven by the gear train and controls the release of power from the mainspring. Typically, the escape wheel has 15 clubs or ratchet-shaped teeth made from steel. The rotation of the escape wheel is controlled by the locking and unlocking process with the pallets on the lever. The escape wheel meshes with the 4th wheel and delivers power from the mainspring to the balance assembly.

Roller or impulse jewel – the connection point between the escape wheel and the pallets, and it sits inside the pallet fork. The roller jewel provides the impulse to the pallet fork, unlocking the escapement.

Pallet fork – meshes with the roller jewel.

Banking pins – limits the travel of the pallet arm.

Pallet arm – extends the reach of the pallet cup.

Pallet jewels – temporarily lock with the escape wheel.

Roller table – mounts the roller jewel and meshes with the guide pin.

The Balance assembly

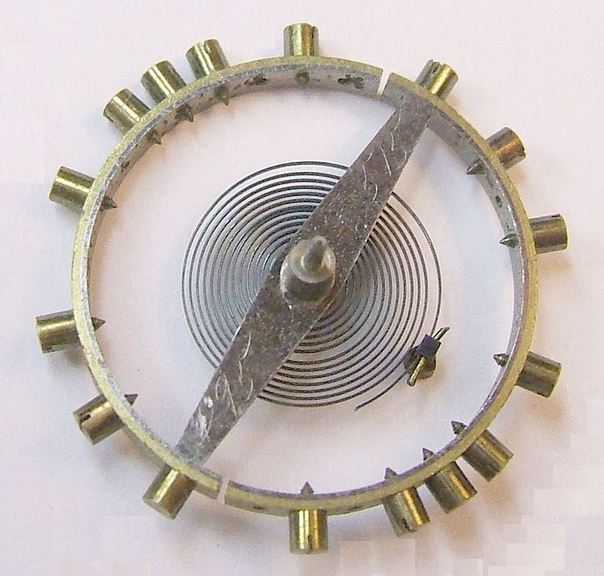

Balance wheel – oscillates to provide timekeeping to the watch.

Hairspring – The hairspring is a spiral torsion spring used in mechanical watches to control the rate of oscillation of the balance wheel. The balance spring and balance wheel form a harmonic oscillator, which oscillates with a precise beat, and is responsible for timekeeping accuracy.

Balance staff – the pivoted axle of the balance wheel.

Collet – attaches the hairspring to the balance staff.

Hairspring stud – anchors the tail end of the hairspring.

Weights – controls the rate and positional accuracy.

Balance wheel construction

The earliest balance wheels were made of solid metal. Later models were bi-metallic with expansion cuts to adapt to changes in temperature. They also included adjustable weights that added mass to control rotation. The rate of oscillation was controlled by a hairspring, and most models had a regulator for making fine timekeeping adjustments.

Related content

Mechanical watch at Wikipedia.

Hi

I have a Lancashire watch company (Prescot) pocket watch how do I find its age from the serial number seems to be only American sites for American watches on line?

Hi David, I am not aware of any online listing of LWC serial numbers. Even if there was, there is no guarantee that the serial numbers were sequential in terms of date. The Lancashire Watch Company was in business from 1889 to around 1911, so your watch will date within this range. If the case is made from silver or gold there will be British hallmarks that will allow you to date the watch. I hope this helps. Thanks, Jason

Thanks Jason

Hi, I have an antique pocket watch that I have recently inherited. It has the same maker, W Hind, that you show in the image labelled Reversing Pinion. I can’t find any information about this watchmaker. Are you able to provide some information? What would the watch be worth? Thanks.

Hi Tonia, I thought the same when I first saw that name. However, it is actually W Hird, a jeweller from Barrow-in-Furness. The watchmaker was most likely the Lancashire Watch Company, William Hird would have then been the retailer that sold the watch. In terms of value, I typically advise that the sentimental value will outweigh the monetary value. However, this post on how to value an antique pocket watch might help. Thanks for commenting, Jason