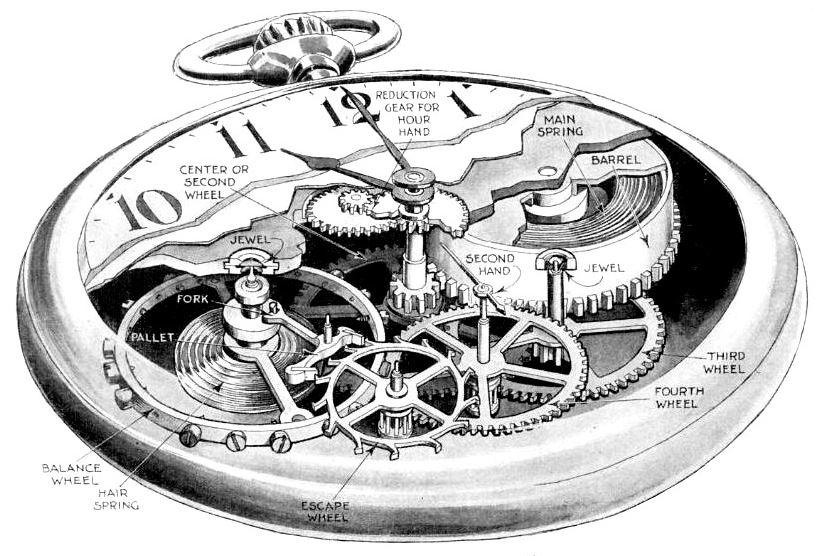

A gear train is a mechanical system formed by fitting gears on a frame so the teeth of the gears engage. Gear teeth are designed to ensure the pitch circles of engaging gears roll on each other without slipping, providing a smooth transmission of rotation from one gear to the next. The gear train on an antique watch is also known as the wheel train and transfers power from the mainspring to the escapement and the balance wheel.

Watch movements are very standardised, and the wheel trains of most watches have the same components. The large gears in watches are generally called wheels and the smaller gears they mesh with are called pinions. The shafts that the wheels and pinions are mounted on are called arbors (axles). The wheels are mounted between the movement plates, with the pivots rotating in the jewelled holes in the plates. The pivot holes have semi-circular depressions around them, called oil cups, to hold the oil in contact with the shaft by capillary action. Typically, a mechanical watch has one gear train responsible for timekeeping. However, some watches may have additional gear trains for complications like chronographs or calendars.

Going train

There are a number of different types of gear trains that might appear in a watch, but we are going to focus on a going train to explain how the movement works. The going train is the main gear train of the timepiece. It consists of wheels that transmit the force of an antique watch’s power source, the mainspring, to the escapement to drive the balance wheel to maintain time.

The going train has two functions. Initially, it increases the speed of rotation of the mainspring barrel. This allows the use of a very strong, slow turning mainspring that will run the timepiece for several days. Second, its gear ratios divide the rotation of the escape wheel into convenient time units of seconds, minutes, and hours, which turns the watch’s hands. The going train wheels are the only ones under constant load in an antique watch since they bear the constant pressure of the mainspring, which is applied to the escapement. These wheels are the only ones that receive significant wear and, in many cases, will use jewels to minimise friction and long-term wear and tear.

The going train in a watch consists of:

First wheel

The first wheel is actually the mainspring barrel, which has a series of teeth on the outside of the barrel. When the mainspring is wound it creates the torque to turn the mainspring barrel, which transfers power to the rest of the gear train. The first wheel interacts directly with the centre or second wheel.

Centre wheel

The centre or second wheel turns once per hour. Its pinion is turned by the teeth on the mainspring barrel. Its arbor projects through a hole in the face and drives the cannon pinion, which carries the minute hand. The centre wheel also drives a component called the motion work. This is a 12 to 1 reduction gear that drives the hour hand from the minute hand. The centre wheel also drives the pinion of the third wheel.

Third wheel

The third wheel simply drives the pinion of the fourth wheel.

Fourth wheel

The fourth wheel rotates once per minute and drives the second hand. The fourth wheel also turns the escape wheel pinion.

Escape wheel

The escape wheel is released one tooth at a time by the escapement, with each swing of the balance wheel. The escape wheel keeps the balance wheel oscillating by giving it a small push each time it moves forward, this power is transferred using the pallet fork.

Related content

Read more about other Movement types and Components.