The mainspring is the power source for all mechanical watches. Traditionally, clocks were powered, firstly by water and secondly by the power of gravity pulling on a weight. Neither of these options is practical for a portable timepiece. For example, imagine walking down the street with a bucket of water balanced on your wrist? It’s not very practical and you are likely to have permanently wet feet.

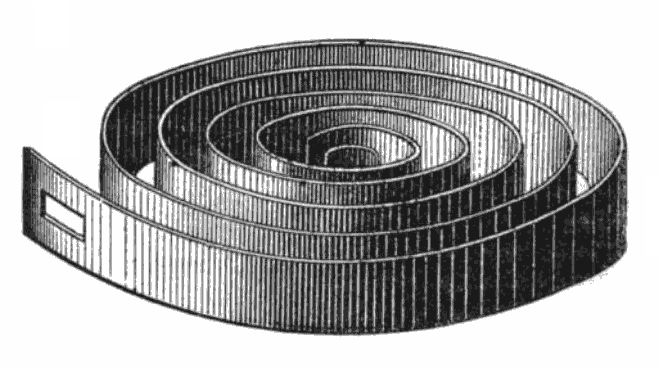

A mainspring is a spiral metal spring used as a power source in mechanical watches and clockwork mechanisms. Winding the timepiece, by turning the crown or a key, stores energy in the mainspring by twisting the spiral tighter. The force of the mainspring then turns the watch’s gear wheels as it unwinds. Eventually, the mainspring will fully unwind and the watch will stop, requiring winding again for the watch to work.

History

Mainsprings appeared in the first spring-powered clocks in 15th-century Europe. It replaced the weight hanging from a cord wrapped around a pulley, which was the gravity power source used in all previous mechanical clocks. Springs were applied to clocks to make them smaller and more portable than the previous weight-driven clocks. Eventually, the technology improved to the point that mainsprings were small enough to make the first practical pocket watches in the 16th century.

The first mainsprings were made of steel without tempering or hardening processes. They didn’t run very long, had to be wound twice a day and were very inaccurate. One of the problems with the early mainsprings was that the force provided by a spring is not constant, but diminishes as the spring unwinds. However, timepieces have to run at a constant rate in order to keep accurate time. So early pocket watches slowed down during their running period as the mainspring ran down, causing inaccurate timekeeping.

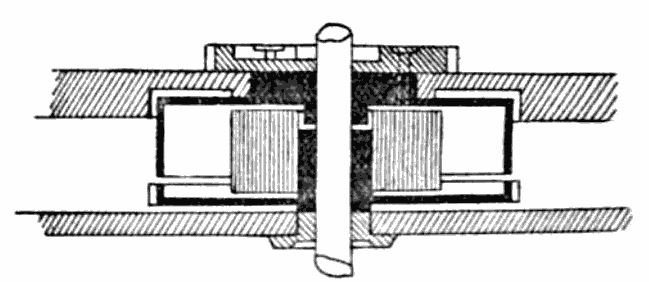

The most common solution used in antique pocket watches for this problem was the fusee movement. This was a gear-like system that applied minimal mechanical leverage when the watch was fully wound. As the mainspring wound down, and the power reduced, the fusee would compensate by increased mechanical leverage. Because of the geared system, timing keeping was more consistent.

How does the mainspring work?

The mainspring is a spiral strip of metal contained in a circular component called the barrel. The outer end of the mainspring is hooked to the inner wall of the barrel. The inner end of the spring is hooked onto the arbor, an axle, within the barrel. The spring will cause either the barrel to turn or allow the arbor to turn independently inside the barrel. By turning the arbor or the barrel the spring can be wound up, storing the energy that makes the watch run.

The barrel arbor is made wider in diameter where the mainspring hooks onto it so that the spring is not bent too sharply at its inner end. This larger diameter element does not have to be made as part of the barrel arbor. It can be made as a separate component called a ‘collet’, which is the French word for a collar. Together, this would be referred to as the arbor collet.

In antique pocket watches with “going barrels” the barrel has teeth on the outside that drive the gear train. To wind the mainspring the arbor is turned, via a key or the crown, so that the spring is wound around the arbor. However, in watches with fusee movements, the outside of the barrel is smooth and one end of the fusee chain is secured to it. Teeth on the bottom of the fusee drive the gear train. As the watch runs and the fusee turns, the chain is drawn off the fusee onto the barrel. To wind the watch the fusee is turned, not the barrel arbor. This draws the chain back and makes the barrel rotate about its arbor, which winds the mainspring.

Carbon steel

Carbon steel was the only material in use for mainsprings for over 450 years. As a result, it had a couple of problems that were never overcome by improvements in the material or technology. Mainsprings made from hardened and tempered carbon steel are prone to breaking due to metal fatigue over many years of use. This often occurred when they were fully wound and their torque was at the maximum. As a result, when they broke, the sudden energy release could strip teeth from wheels or damage jewel bearings. The other problem is that carbon steel springs are not eternally elastic and over time they become less flexible. This means their curvature becomes set and can store less energy.

Mainsprings can also be dangerous when taking apart the movement. Because they store a lot of energy when wound and, when released from the barrel, can fly out and cause serious injury. Always, make sure the mainspring is fully unwound before working on an antique pocket watch movement.

Read more about other Movement types and Components.