The escapement is a key component of an antique watch movement. It controls the transmission of power from the gear train into a series of impulses that are passed to the balance wheel. The ticking sound you hear when holding a watch to your ear is from the escapement. The sound is generated when the pallet fork locks and unlocks with the escape wheel at each vibration of the balance wheel. I’m not sure why, but I have noticed that the ticking on an antique timepiece tends to be a lot louder than a modern mechanical watch.

If the escapement didn’t exist, a fully wound watch would unwind uncontrollably in a matter of seconds. The escapement controls the release of power from the wound mainspring. It is done in such a way that a fully wound watch can run for several days.

Origin

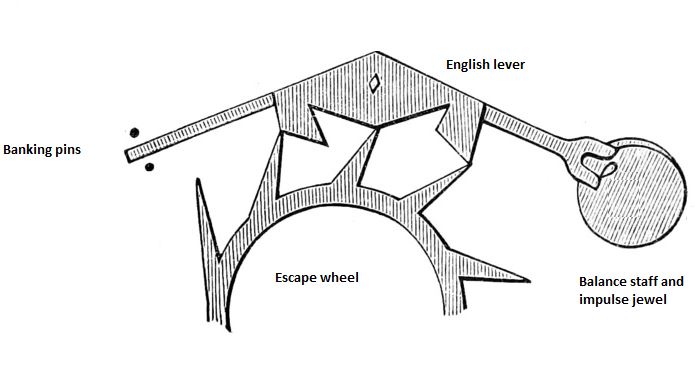

In around 1750 the English horologist, Thomas Mudge, first invented the lever escapement at his workshop in London. There are a number of different types of escapement. However, for the purpose of this article, we are going to discuss the Swiss lever movement that evolved from Mudge’s original invention. The Swiss lever movement appeared in the mid-19th century and is still used in the majority of mechanical watches today. The English lever escapement, is slightly different, as it changes the positioning of the wheels. Whereas the balance wheel, lever and escape wheel are in a straight line in a Swiss lever design, with the English lever they form a 90-degree angle.

Escape wheel

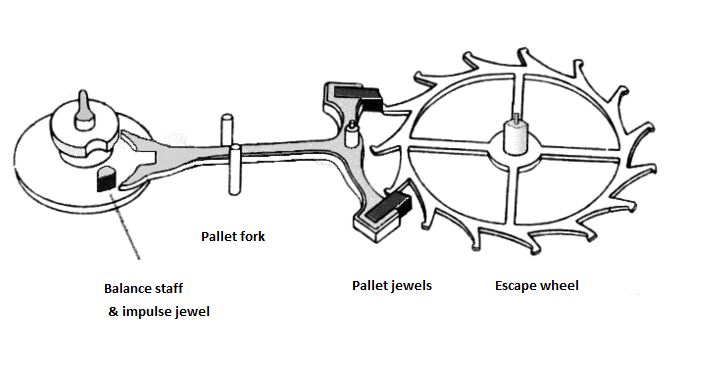

The escape wheel pinion meshes with the fourth wheel of the gear train, which supplies power to it from the mainspring. The escape wheel has 15 teeth and is constructed of steel. The rotation of the escape wheel is controlled by the pallet jewels. These sit on the left and right sides of the pallet fork. The pallet jewels are adhered to the pallet fork by shellac. The escape wheel has specially shaped teeth designed to interact with the two pallet jewels.

At the end of the pallet is a lever, which has a fork designed to receive the ruby impulse pin of the balance roller which is fixed to the balance wheel shaft. The balance wheel is returned towards its static centre position by an attached balance spring. The lever is mounted on a shaft and is free to move between two fixed banking pins.

At rest one of the escape wheel teeth will be locked against a pallet. As the escape wheel rotates clockwise, the escape wheel tooth is locked in place against the pallet and the lever is held in place by the left banking pin. The impulse pin is located within the lever fork and rotates according to the balance wheel. To get started, the lever fork must receive a small nudge from the anti-clockwise rotation of the balance wheel via the impulse pin, which rotates the lever slightly clockwise off the left banking pin. This unlocks the entrance pallet allowing the wheel to rotate clockwise a small distance until it is locked by the escape tooth interacting with the other pallet jewel.

Cycle

The impulse received by the entrance pallet as the tooth moves over the impulse face is transferred by the lever to the balance wheel via the ruby impulse pin on the roller of the balance wheel. The lever moves until it rests against the right banking pin; it is held in this position by the force of the exit tooth against the exit pallet jewel (called the draw). This means that in order to unlock the wheel it must be turned backwards by a small amount, which is done by the return momentum of the balance wheel via the impulse pin. At this point, the lever will be resting against the left banking pin. The balance wheel rotates back from the opposite direction nudging the lever fork to move back towards the left banking pin. As a result, the cycle starts again.

Each back and forth movement of the balance wheel from and back to its centre position corresponds to a drop of one tooth. This is called a beat.. A typical watch lever escapement beats at 18,000 or more beats per hour. Each beat gives the balance wheel an impulse, so there are two impulses per cycle. Despite being locked at rest most of the time, the escape wheel rotates typically at an average of 10 rpm or more.

Read more about other Movement types and Components.