Last updated on June 27, 2024

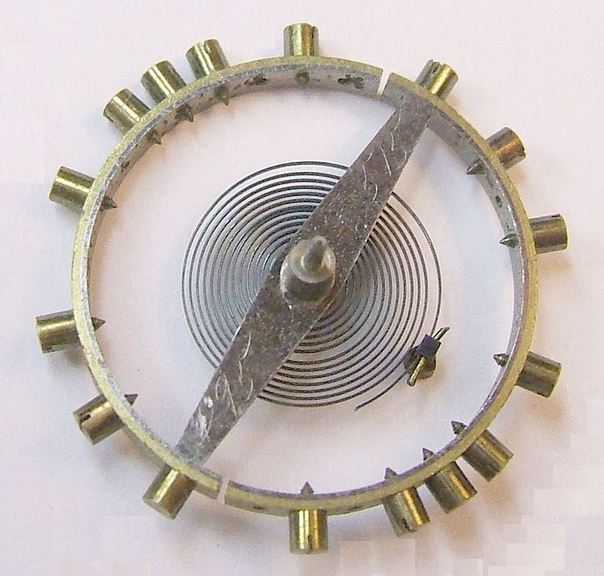

The balance wheel is the timekeeping component of a watch movement. Balance wheels in antique watches are either plain or compensated. A plain balance wheel is generally constructed of steel or brass. Typically, they have three arms acting as spokes to connect the balance staff to the circular rim.

The timing of the balance is controlled by the attached hairspring and its relative strength. A strong hairspring will cause faster vibrations. In contrast, a weak hairspring causes slower vibrations. Both the balance and the hairspring are affected by changes in the temperature. This is because metal expands as it is warmed and contracts as it cools. The elasticity of the hairspring’s metal decreases significantly as the temperature increases. The effect of this change is that a plain steel spring becomes weaker with increasing temperature. In addition, the balance itself expands as the temperature rises, this causes the rim to increase in size, moving the weight further from the centre and causing it to move more slowly.

Temperature effects

The net effect of an increase in temperature is to cause the watch to run slowly. This can be up to several minutes a day during normal temperature conditions. It doesn’t have to be temperature changes due to the weather. Moving from the cold outdoors into a warm household could cause a significant increase in temperature. A more subtle change would be taking the watch from an overnight stand and putting it into a pocket, where it is exposed to body heat.

Watches before the 20th century used plain steel balance springs. These were highly susceptible to changes in elasticity as the temperature changed, which could disrupt the accuracy of a watch. However, watchmakers discovered a way to offset the effect. The balance was made of two strips of brass and steel fused together. Two cuts were then made in the balance’s perimeter. This allowed the balance to expand and contract. The end result was that the balance changed in size as the temperature changed, which almost exactly cancelled out the change in the elasticity of the hairspring.

First compensated balance

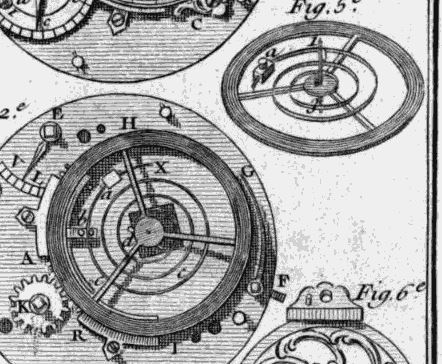

The very first compensated balance was developed by John Harrison in the mid-18th century, for his H4 marine chronometer. Later watchmakers, such as Thomas Earnshaw and John Arnold, gradually refined this initial design.

The key was to make the balance wheel change size with temperature. If the balance could be made to shrink in diameter as it got warmer, the smaller moment of inertia would compensate for the weakening of the hairspring. This would keep the period of oscillation constant. In order to achieve this constant, the outer rim of the balance was made using strips of two metals. An inner layer of steel was fused to an outer layer of brass. This bimetallic balance would bend toward the steel side when they are warmed because the thermal expansion of brass is greater than steel. The rim was cut open at two points next to the spokes of the wheel, so it resembled an S-shape with two circular bimetallic arms.

A temperature increase makes the arms bend inward toward the centre of the wheel. The shift of mass inward reduces the moment of inertia of the balance. This reduction in the moment of inertia compensated for the reduced torque produced by the weaker balance spring. The amount of compensation is adjusted by moveable weights on the arms. This type of compensated balance began to be used in watches in the 1870s. The bimetallic compensated balance wheel was made obsolete in the early 20th century by advances in metallurgy.

Related content

Balance wheel at Wikipedia.

Useful post, I have an antique Omega pocket watch, it has what I now know to be a compensated balance. My watch was a retirement gift. It is a silver open faced pocket watch and dates to 1908. Thanks for the information.