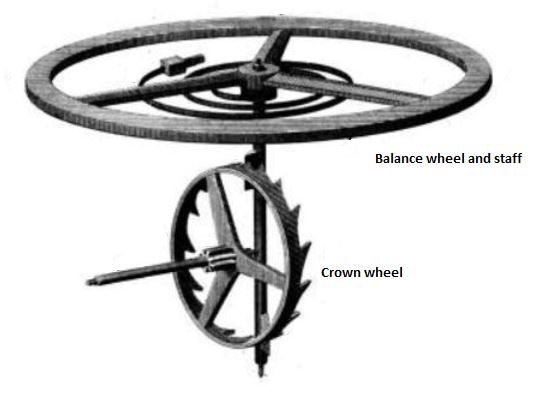

The verge escapement is the earliest known type of mechanical escapement. It is also known as the crown wheel because of its appearance. The escapement is the mechanism in a mechanical timepiece that controls the transmission of power from the gear train to the balance wheel. The origin of the verge and its inventor are unknown. However, verge escapements were used from the 16th century until the mid-19th century in pocket watches. The name verge comes from the Latin virga, meaning stick or rod. The rod or stick, in this instance, is the balance staff, which acts as the axle for the balance wheel. There are two pallets on the balance staff that engage with the teeth on the verge or crown escape wheel.

The verge escapement is an important part of horological history because it made the development of mechanical timepieces possible. Prior to the verge escapement, measuring time was restricted to the flow of water or the movement of the sun. The verge escapement also allowed portability and facilitated the creation of the portable timepiece, the pocket watch.

How it works

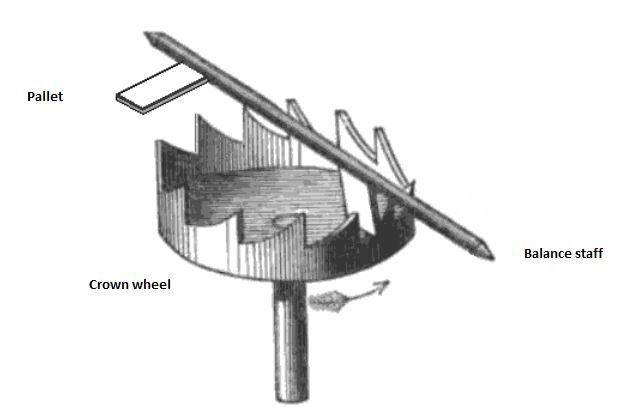

The verge escapement consists of an escape wheel shaped like a crown, with teeth angled forward in the direction of movement. The axis of the escape wheel is oriented horizontally. Interacting with the escape wheel is the balance staff or verge. The staff is fixed with two metal pallets, that engage the teeth on opposite sides of the crown wheel. The pallets are set at an angle so that only one of them can interact with the crown wheel at any one instant. The balance wheel sits on the end of the verge rod.

As the gear train turns the crown wheel, one of its teeth pushes on a pallet, rotating the verge in one direction. Simultaneously, the second pallet rotates into the path of the teeth on the opposite side of the wheel, until the tooth pushes past the first pallet. Then a tooth on the wheel’s opposite side engages the second pallet, rotating the verge back in the other direction. The cycle then repeats. Each beat of the balance wheel allows one tooth of the escape wheel to pass. This advances the gear train of the watch by a fixed amount, facilitating the timekeeping process.

The crown wheel must have an odd number of teeth for the escapement to function. If the crown wheel had an even number, two opposing teeth would contact the pallets at the same time, locking the escapement.

Disadvantages

The verge is the most inaccurate of the most commonly used escapements. It suffers from the following problems, which are generally due to wear and tear:

Verge watches are very sensitive to changes in the drive force and they tend to slow down as the mainspring unwinds. As a result, all verge watches required a fusee to equalise the force of the mainspring to achieve even minimal accuracy.

The escapement has “recoil”, meaning that the momentum of the balance wheel pushes the crown wheel backwards momentarily. This causes the gear train to move backwards, during part of its cycle. This increases friction and wear, resulting in inaccuracy.

Verge watches tend to accelerate as the crown wheel and the pallets wear down. It is not uncommon for these watches to gain many hours per day.

Decline

For centuries the verge escapement was the only viable movement for pocket watches. However, it was eventually superseded by more accurate movements. The cylinder movement was adopted by French watchmakers in the late 17th century and the lever movement was developed in the late 18th century. Both of these later movements were more accurate and reliable. The lever movement became commonly used from the mid-19th century and remains in use today. The verge movements continued to be produced well into the 19th century as they were cheaper to produce than the newer movements.