The cylinder escapement was invented in England by Thomas Tompion (1639–1713) in 1695. It was perfected in 1726 by George Graham, an apprentice to Tompion. It was also known as the horizontal escapement, in contrast to the vertical verge escapement that preceded it. The cylinder escapement was never commonly embraced by English watchmakers. However, it was widely used in France and Switzerland until the early 20th century. Once the English Lever escapement had been perfected in the early 19th century the use of cylinder escapements in England was abandoned completely.

The major attraction of the cylinder movement was its relative thinness when compared to the verge escapement. This allowed pocket watches to be made fashionably thinner than was possible with the verge escapement. However, like the verge escapement, the cylinder escapement was highly susceptible to excessive wear as the components were in constant contact throughout the cycle. This resulted in wear through constant friction. This is particularly the case with brass and steel movements used by the English watchmakers. The French and Swiss greatly reduced the wear and tear by using hardened steel and jewelled cylinders made from ruby.

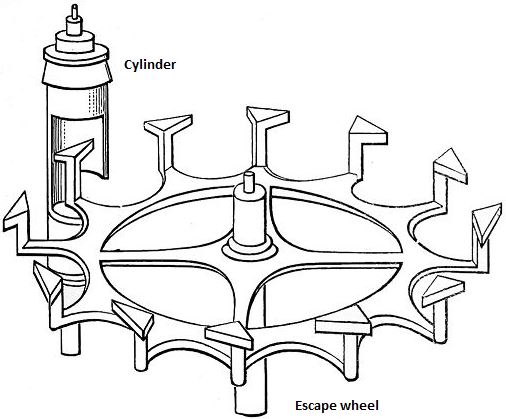

How it works

The cylinder is part of the balance staff, on top of which, the balance wheel sits. The cylinder has a section cut out, as seen in the diagram below. The teeth on the escape wheel interact with both the inner, cut-out section of the cylinder and the solid outer wall of the cylinder case. As a tooth enters the cut-out section, it will push against the inner cylinder wall to transfer power from the gear train to the balance wheel. The next tooth on the escape wheel will then lock against the solid outer wall of the cylinder. The balance wheel then turns, which rotates the cylinder to reveal the cut-out section. This releases the tooth from the outer wall of the cylinder and allows it to enter the cut-out and transfer more power to the balance wheel. The cycle then repeats.

The constant friction of this movement is what causes the significant wear and tear. The escape wheel teeth and the cylinder are in constant contact throughout the cycle. If dust enters the movement and mixes with the lubricants it can create an abrasive paste that exacerbates the damage. The chief advantages of this movement are its simplicity, low cost and the fact that it is easy to manufacture and adjust. Cylinder watches continued to be manufactured well into the 20th century. The downside of this movement is the requirement for frequent servicing to minimise the effect of friction. It is for this reason that I avoid adding watches with cylinder movements to my collection.

Related content

Thomas Tompion at Wikipedia.

George Graham at Wikipedia.