Early mechanical clocks were powered by a weight, the constant pull of gravity providing the energy to power the movement. However, this is not practical for a personal clock, otherwise known as a watch. After all, no-one wants to walk down the street with a kilogram of lead hanging from a cord on their wrist. The invention of the spring-powered movement in the 15th century, suddenly made personal timepieces practical.

The problem with spring-powered movements is that the energy provided by the springs reduces as they unwind. If you are old enough to remember clockwork toys, you will recall that a spring-powered car will accelerate rapidly when released, but slow drastically as the spring unwound. Apply this to a watch and you will have a timepiece that becomes significantly less accurate as the spring unwinds. However, there was an ingenious solution to the loss of torque as the spring unwinds, the fusee. I have heard this pronounced as fu-see from antique watch experts. The word comes from the French fusée, meaning wire wound around a spindle.

The fusee works using a geared system, which offsets the loss of torque as the spring unwinds and provides a consistent source of energy. It’s similar too, and looks like, the derailleur gear on a bike. The fusee is a conical shape with a spiral groove in which the chain sits. No-one knows who invented the first fusee movement, but an illustration from Leonardo Da Vinci in 1490 shows a fusee on a machine of an unknown purpose. The earliest known clock with a fusee, also the earliest existing spring-powered clock, is the Burgundy clock, believed to have been made for Phillipe the Good, Duke of Burgundy (c. 1430) which is now in the German National Museum.

How does it work?

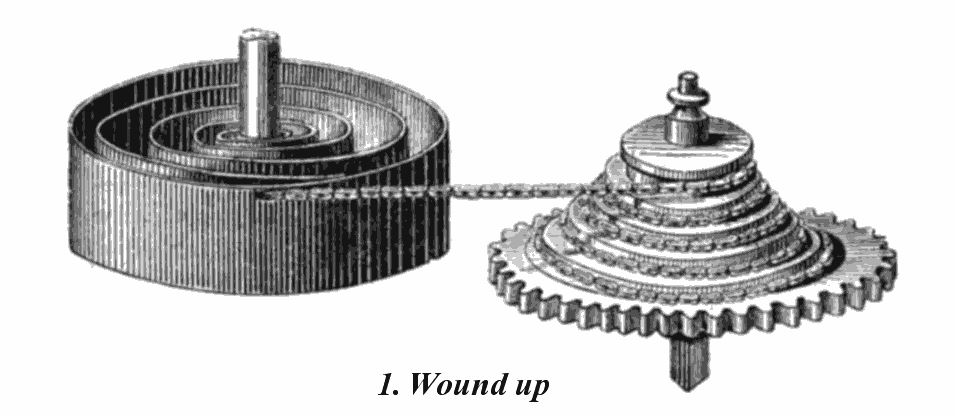

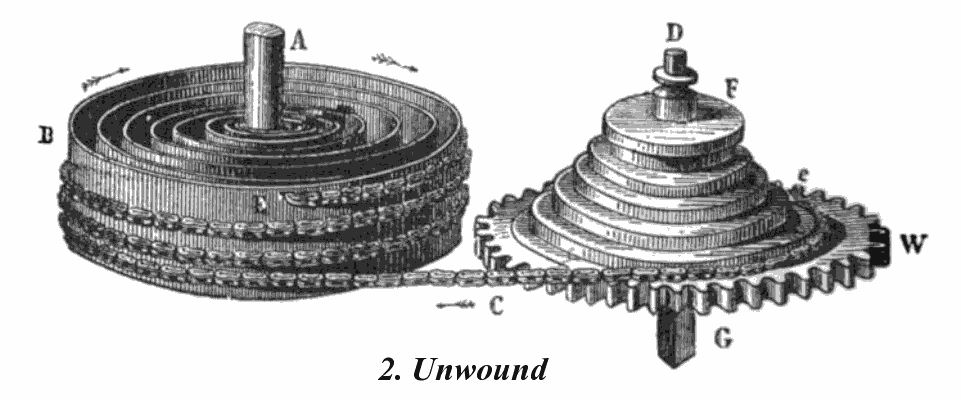

As previously mentioned, it is much like the gears on a bicycle. The mainspring is coiled around a stationary axle (arbor), inside a circular box, called the barrel. The force of the spring turns the barrel, which provides the pocket watch or clock with its power. In a fusee pocket watch, the barrel turns the fusee by pulling on the chain, and the fusee turns the pocket watch gears.

When the mainspring is fully wound, all of the chain is wrapped around the fusee from the top to the bottom. The end of the chain coming from the barrel comes off the narrow top end of the fusee. The strong pull of the fully wound up mainspring is applied to the small end of the fusee, and the torque on the fusee is reduced by the small lever arm of the fusee radius. As the pocket watch runs, the chain is unwound from the fusee from the top to the bottom and wound around the barrel. Note: when winding a fusee movement the tension doesn’t increase as the spring is wound. This is due to the gear effect of the fusee itself, the tension should remain constant as the key is turned.

As the mainspring runs down and loses torque, more of the chain is coiled in the groove around the barrel. The chain coming from the barrel is pulling against the wider bottom grooves of the fusee. Now, the reduced torque of the mainspring is pulling against the larger radius at the bottom of the fusee. The greater turning moment provided by the larger radius at the fusee compensates for the loss of force from the spring, keeping the drive torque constant.

To think of this another way, imagine you are on a cycle ride on a constant incline. Early in your ride, your legs are full of energy and you find it easy to turn the pedals in one of the higher (smaller) gears. As you tire, you have less energy to turn the pedals. To compensate you change the gears so that you are using one of the larger cogs in the mechanism. Less effort, power or torque is now receiving the same result, a single turn of the wheel.

To wind the pocket watch up again, a key is fitted to the winding arbor of the fusee and the fusee is turned. The pull of the fusee unwinds the chain off the barrel and back onto the fusee, turning the barrel and winding the mainspring. The presence of the fusee means that the force required to wind up the mainspring is constant. Unlike more modern watches, the tension does not increase as the mainspring tightens. Once you feel resistance, it is important to stop winding as you risk snapping the chain.

Most fusee clocks include a mechanism to prevent the mainspring and fusee from being wound up too far. As it is wound, the fusee chain winds toward the top of the fusee. When it reaches the top, it presses against a lever, which triggers a mechanism which prevents further winding. Overwinding a fusee movement can result in a broken chain, which can seriously damage the workings of a pocket watch.

The gear on the fusee drives the movement’s wheel train, usually the centre wheel. There is a ratchet inside the fusee, which prevents it from turning the clock’s wheel train backwards while it is being wound up. In high-end watches, there is also a maintaining power spring. This supplies a temporary power source to keep the movement running whilst it is being wound. This type of movement is called a going fusee. It is usually a gear mechanism in the base of the fusee, which then provides power to keep the pocket watch running during winding.

Decline of the fusee movement

The fusee was an innovative concept and helped improve the accuracy of early spring-powered pocket watches. However, there were a few disadvantages. They were expensive and difficult to maintain. They were also tall, for a watch component, and required pocket watches to be thick and bulky. Also, if the mainspring broke and was replaced, the fusee would have to be recalibrated for the new mainspring.

In pocket watches, the verge escapement, which required a fusee, was gradually replaced by escapements (cylinder and lever) which were less sensitive to changes in the mainspring force. These new movements used mechanisms and materials that made them more accurate and the bulky fusee was no longer required. By 1850, the Swiss watchmaking industry was using the new movements and had dispensed with the fusee. England continued to make fusee watches until about 1900, but these were for generally inexpensive models that were nicknamed “turnips” (including Sir Winston Churchill’s pocket watch).

Related content

Fusee (horology) at Wikipedia.

Read more about other Movement types and Components.