Last updated on June 26, 2024

In this post, we are going to look at the main factors that indicate a high-quality antique pocket watch. Whether you are looking to start a collection or to evaluate an inherited timepiece, these seven categories are points to consider.

1) Case material and finish

Watch cases are made from many different materials. Some of them, such as steel, nickel and gunmetal, are used for their relatively low cost and durability. However, higher-quality watch cases are almost always going to be made from a solid precious metal alloy, such as gold or silver. Precious metals are by nature very soft, so to improve their durability they are generally alloyed with a harder metal. The quality of the precious metal will generally be indicated by a hallmark stamped on the case. It is possible, but highly unlikely, that you would place a low-quality movement in an 18ct gold case. Therefore, the quality of the case material is a good indicator of the quality of the watch movement inside.

2) Jewel count

Most mechanical watches have at least 7 jewels contained in the balance and lever mechanism. 7-jewel watches should typically be avoided as they are of lower quality and susceptible to wear and tear. A jewel count of 15 and above would be of mid or higher quality. In the late 19th century 15 jewels were considered the standard for a “fully jewelled watch”.

Movements with 17 or more jewels contain hole jewels for the entire gear train, giving the movement improved accuracy and longevity. Jewel counts greater than 17 certainly improve other aspects, but a jewelled gear train helps reduce friction in the most important areas. Lower-quality movements are typically not marked with a jewel count. Additionally, sometimes the manufacturers would also only place jewels on the visible parts of the movement, using metal bearings on the hidden parts of the movement.

3) Compensated balance wheel

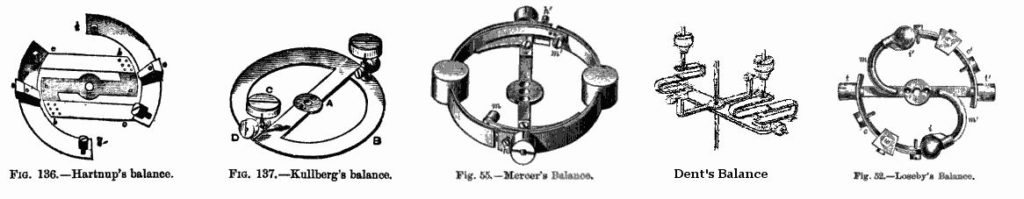

The balance is the timekeeping component of a mechanical watch. Being made of metal the balance wheel and the hairspring are sensitive to changes in temperature, which can impact accuracy. Therefore, all balances in watches of any quality were “compensation” balances. A compensation balance compensates for the effects of temperature on the hairspring. The most common compensation balance is a bimetallic balance, also known as the Earnshaw balance.

The rim of the wheel is made of brass on the outside layer and steel on the inside. The wheel rim was cut open at two points next to the spokes of the wheel, creating two semi-circular bimetallic ‘arms’. Because brass expands less with increased temperature than steel does, the rim ends curl inward with a temperature rise. This effectively reduces the diameter of the balance wheel. This increases its speed and offsets the temperature effects on the hairspring. In contrast, the rim ends curl outwards with a drop in temperature, increasing the effective diameter of the balance and slowing the watch.

4) Adjustments

Quality watches were adjusted at the factory to improve accuracy in a variety of circumstances. This is because of the effect of gravity on the movement of the watch. The effect on the movement will change according to the position in relation to the pull of gravity. For example, if we imagine that the pocket watch is lying dial-up on a table the pull of gravity will have a different effect on the components than if the watch was sitting upright in a waistcoat pocket. Typically, more adjustments indicate a higher quality movement. The highest quality movements are adjusted to five or six positions, temperature, and isochronism. The number of adjustments is usually engraved on the movement.

5) Regulator

Micrometer regulators are typically used on higher-quality movements. This allows precision adjustments to be made to the swing rate of the balance wheel. This will alter the speed of the watch. Regulating an antique watch means making it run slightly faster (F/A) or slower (S/R), by making a small change in the effective length of the balance hairspring. The shorter the effective length, the quicker the balance completes its swing and so the watch runs faster. All movements will contain a regulator, but lower-quality movements usually do not contain an additional mechanism to allow for precision incremental adjustments.

6) Sunk dials

This is a simple way to assess the quality of an antique pocket watch without even inspecting the movement. A “sunk dial” on a pocket watch refers to the layering of various sections of the dial to create a more polished end product. Typically, the two areas of the dial that were “sunk” were the centre (inside the chapter ring) and the seconds sub-dial. A single-sunk dial usually just had the seconds-dial recessed, and a double-sunk dial usually had the centre and seconds sub-dial recessed. The sunk seconds sub-dial also serves the purpose of allowing the second hand to sit a little lower. This gives greater clearance to the hour and minute hands above.

Sunk enamel dials were made by grinding out a hole in the main dial and then soldering in the separate sunk sub-dials. Therefore sunk enamel dials took more time and effort to manufacture. As a result, these dials were typically reserved for watches of higher quality. However, while this is not always the case, it is an excellent indicator. Be aware that a painted black line imitating the second sink is common. If examined closely under magnification it should be obvious if the line is painted on the dial. Also, note that a double-sunk dial could be taken from a donor watch and fitted to a timepiece of lesser quality.

7) Screw-set jewels

Screw-set plate jewels are attached to the movement plate with small screws called chatons. The heads of the screws will sit flush with the movement plate. This required more material and more time to assemble. As a result, screw-set jewels were commonly fitted into movements of higher quality. Screw-set jewels are also considerably easier to replace if one is cracked or broken. In contrast, friction-set jewels were less expensive and repairs required much more effort. As a result, higher-quality movements almost always contain screw-set jewels, especially before 1930. There are also raised screw-set jewels. These appear on higher grades of watches. Being raised above the surface of the watch plate, the pivots of the gear train can be longer. This adds greater strength and durability to the pivot.

A high-quality antique pocket watch will include, perhaps all of these features.

A list of additional posts regarding antique watches can be found on the Guides page.

Aren’t modern pocket watches high tech, and higher quality than antiques?

Hi Petros, typically no. Some modern pocket watches are quartz. Those that are mechanical, like all antique pocket watches, use the same technology, which hasn’t changed much over the last 200 years. Antique pocket watches have a quality and character that modern timepieces cannot match. Thanks for commenting, Jason